Understanding the differences between a battery monitoring system and a battery management system.

Why safety? Common approaches

The race for the best lithium ion battery is a worldwide competition. However, designing the most energy dense cell is only one leg of this race. One of most desirable characteristics of lithium ion batteries is their energy storage capacity and capability to release the energy in a controlled manner. There is a consequence to packing so much energy into a small space: when the energy is not released in a controlled manner battery failures can occur, which can result in very powerful explosions and hot fires. Therefore, another aspect of this race for the best battery is innovative safety approaches to prevent and mitigate battery failures.

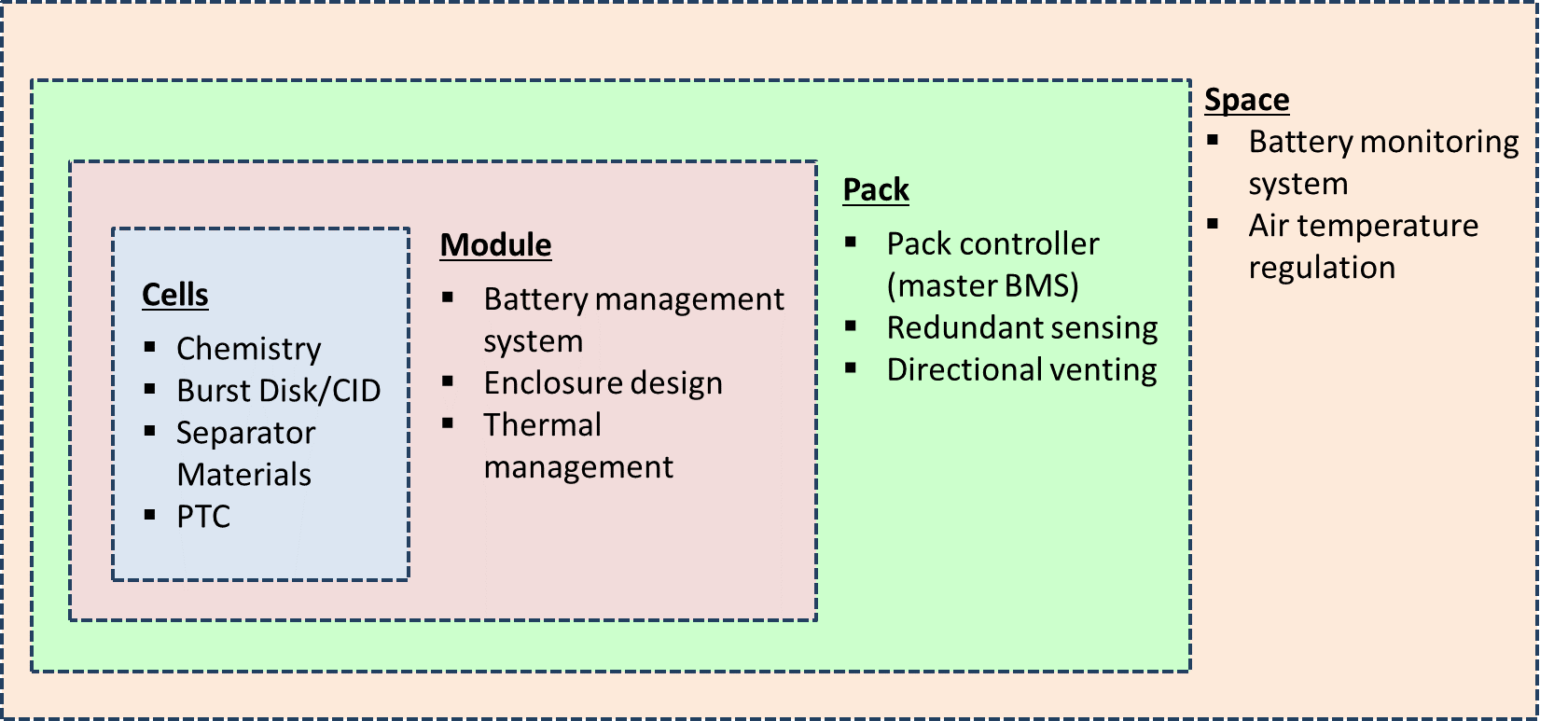

Each and every component of a lithium ion battery system has safety mechanisms to guard against battery failures. The hierarchy of a large format li-ion battery system is shown in the figure below along with common safety features of each component.

Battery Management System

There are many innovative approaches to improving the safety of battery systems, especially large format lithium ion batteries. One of those most critical safety innovations was the battery management system. The duty of the battery management system is to keep all lithium ion battery cells within their precise operational window. This “operational window” entails many different characteristics, such as current, temperature, and voltage.

A typical battery module will have multiple lithium ion cells in series and parallel configurations, which means they are being discharged or charged simultaneously. Battery manufacturers do their best to produce cells that are identical; nevertheless, cells can still age differently due to location in the module or inherent small differences in the cell. One of the primary duties of the battery management system is to ensure that cells are properly balanced. If cells are unbalanced at the beginning or end of a charge/discharge cycle, they will enter ranges outside of their operational voltage window, which will quickly degrade the cell and decrease the functionality and performance of the module as a whole. This can also make the battery much more likely to fail. For this reason, it is necessary that individual cell voltage monitoring is performed and the proper circuitry and logic exist at the module level to keep the cells within their voltage window while they are being charged and discharged.

Lithium ion cells also have specified temperature windows and maximum charge and discharge current limits. The battery management system calculates the maximum charge and discharge current a module can withstand and has the proper circuitry to protect against currents that are above these limits. The battery management system also monitors the temperature of the module, and the most advanced battery management systems measure individual cell temperatures.

Battery Monitoring Systems

Without battery management systems, lithium ion batteries would truly not be able to be the energy storage technology of today and the future. However, where battery management systems fall short is when a lithium ion battery failure actually occurs. If cells are properly monitored, balanced, and treated how they were designed to be treated, a battery failure should not occur. Yet battery end users treat batteries in ways we could never imagine. Even sometimes when batteries are treated properly throughout their entire life, manufacturing defects still can cause battery failures. Ultimately, a battery management system is a circuit board with discrete inputs and defined logic and control capability. Additional monitoring of the battery system beyond electrical interrogation and temperature measurements can provide additional information regarding the state of health of the battery system. This is where battery monitoring systems provide value.

Where battery management systems fall short is when a lithium ion battery failure actually occurs.

A battery monitoring system is a crucial component of a large format lithium ion battery. One of the most critical dangers of a battery failure is the flammability of the electrolyte which can lead to a cell venting flammable gases during their failure. When a battery cell reaches thermal runaway, it generates its own heat and oxygen. The temperatures a cell can reach during thermal runaway exceed the auto ignition temperature of the solvents in the electrolyte and, therefore, the electrolyte contributes to the battery failure. Another critical danger is propagation, when a single battery failure causes adjacent cells to fail the event can spread to all cells in the pack, and even adjacent modules. The amount of energy stored in a single module can cause a spectacular and catastrophic fire when the cells begin to propagate. However, a proper battery monitoring system can enable the prevention of these dangers and will be able to help mitigate them.

A typical battery monitoring system can offer smoke detection with audible and visual alarms with a redundant heat sensing for initiating fire suppression, such as room level sprinklers.

A state-of-the-art battery monitoring system can offer off-gas detection for early indication of battery failures along with smoke, heat, and flame detection for diagnosing the stages of a battery failure (check out stages of a battery failure white paper here).

These systems can also provide module-level fire suppression so that fire suppressant can be injected directly into a battery module during failure. Battery modules are often designed to be air and water tight so a typical sprinkler system may not be an appropriate solution for mitigating battery fires with these types of modules.

There is plenty of bad press surrounding lithium ion batteries and with numerous industry leaders issuing recalls because of faulty lithium ion batteries, there is an uneasy air surrounding lithium ion battery safety. Utilizing advanced battery management systems in addition to battery monitoring systems can enhance the safety of lithium ion batteries and facilitate their adoption into new applications. The proper solutions exist so that battery failures can be avoided and at the very least mitigated, people just need to be made aware of them.

|

Upgrade your battery management system into a monitoring system. |

|

|---|---|

|

Contact the experts at Li-ion Tamer® to learn how you can upgrade your system today. |

|