The UL 9540A test method continues to set the standard for battery energy storage safety testing. The method quickly answers questions regarding the ability for a lithium-ion battery energy storage system (ESS) to deal with thermal runaway. UL 9540A creates a level playing field for all battery manufacturers and system integrators. It challenges their system’s design and its capability to deal with cell-to-cell, module-to-module, and rack-to-rack failure propagation. A single lithium-ion battery releases an enormous amount of energy when it catches on fire and can exceed temperatures of 1000C. This can severely thermally abuse adjacent cells and cause them to enter thermal runaway.

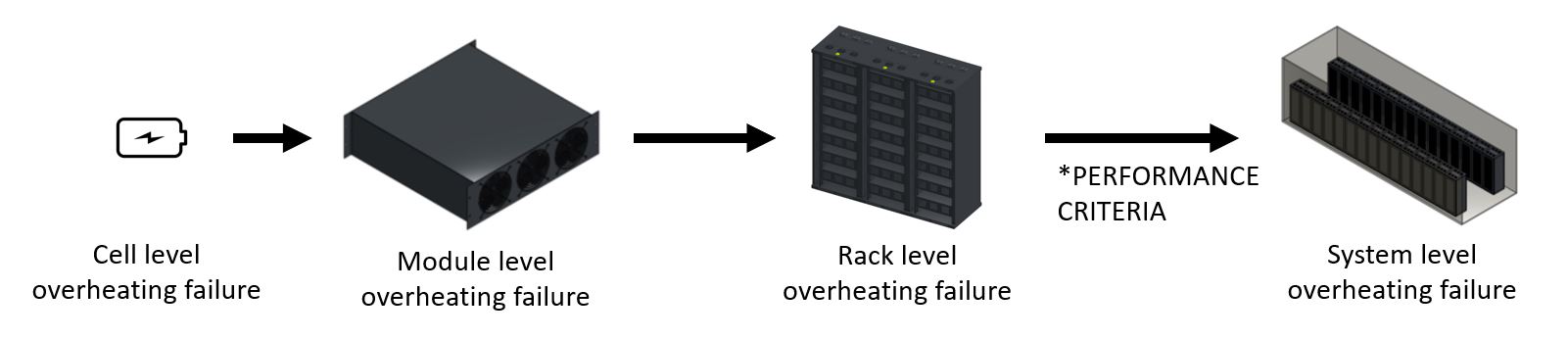

The four tiers that summarize the test method are as follows: cell, module, rack, and installation (system) failure testing.

A critical component of the UL 9540A test method is that abuse of systems continues until failure. Typically, heating single or multiple cells at 5C/minute results in thermal runaway. By abusing the smallest repeat unit of the system, the test is understanding the extent to which that failure propagates.

While in operation, a battery management system would likely detect temperature or voltage anomalies. UL 9540A assumes these systems are non-functional and that a cell has reached thermal runaway. In doing so, it judges the systems’ capability at responding to thermal runaway. In fact, the cell level test is designed around figuring out how to repeatedly force the cell to fail.

The test method generates a wealth of information for sharing with authorities having jurisdiction (AHJ) or end users. The AHJ will have this information available when looking to issue a permit for a specific project or system that has gone through the UL 9540A test method. On the other hand, end users may use it when reviewing proposals from several companies for comparison.

The test notes specifically to differentiate between a cell venting (6.2.5) and a cell in thermal runaway (6.2.6) shown below.

6.2.5 The temperature at which the cell case vents due to internal pressure rise shall be documented.

6.2.6 The temperature at the onset of thermal runaway shall be documented.

UL is on the forefront of battery failure testing and has one of the first standards organizations to recognize this phenomenon. When the first cell vents gas is one of the most critical stages of a battery failure. Given proper mitigating actions are taken, off-gas detection can help prevent battery failures at this particular stage.

If you are interested in learning more about our product and how to integrate it into your systems to prevent thermal runaway, please contact us.

| Contact us to schedule a webinar |

|---|