We are honored that Nexceris’ Li-ion Tamer was featured in PV Magazine in late October. What follows is the content from the article.

Nexceris: Taming the Li-ion

In an emergency, every second counts. With this premise in mind, a team from Ohio-based manufacturer Nexceris set out to improve a warning system to protect lithium-ion storage systems from fires, after working with the U.S.

Navy on the response to a lithium-ion fire outbreak on a vessel 10 years ago.

Though an unpopular topic, a look toward South Korea brings the extent of the battery fire issue into focus. In the last 18 months, we have seen 23 fire outbreaks in large-scale lithium-ion storage systems in the country, with 500 currently still shut down, pending safety reviews. Randy Stacy, the chief commercial officer of Nexceris, claims that the issue is prominent in South Korea because it has such a large fleet already installed.

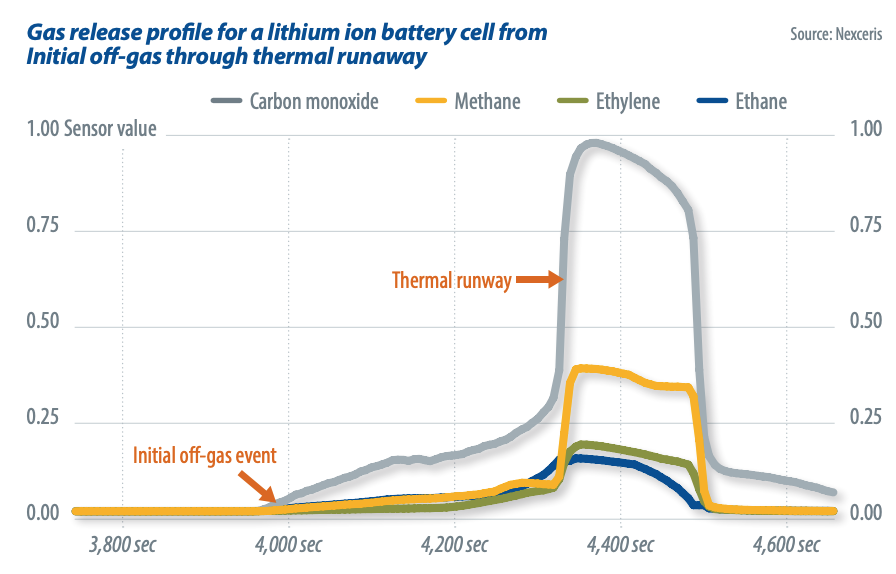

If a fault occurs with a battery cell – either by production failure, temperature, mechanical or electrical abuse – the electrolyte inside the cell will begin to break down, setting off a sequence that ends with a thermal runaway event, or a battery in flames, in layman’s terms. The sequence is outlined in the UL 9540A testing method for evaluating thermal runaway containment in lithium-ion batteries. Gases release as a result of electrolyte breakdown, which leads to pressure buildup in the battery cell, until the gases vent, which is dubbed “off-gassing.” Only after the venting has occurred, the temperature rises, followed by smoke emissions and eventually the outbreak of fire. So rather than relying on smoke and temperature sensors, Nexceris trusts gas detectors to identify issues at an earlier stage.

The time between the start of off-gassing detection and thermal runaway can vary significantly depending on the nature and intensity of the problem.

“In most cases, we are detecting the offgassing between eight to 12 minutes before the thermal runaway,” Stacy says. He adds that anything between two to 30 minutes is possible, however. In this time, the system will communicate with the battery management system (BMS) or the system operator to electrically isolate the faulty cell and have it replaced.

“The BMS and the cell manufacturing quality are the first two lines of defense,” Stacy explains. There are thousands of cells integrated into a utility-scale project, so it cannot be assured that none of them will, at some point, stop working flawlessly. The same goes for battery management systems, which can have shortages. The company says that the Li-ion Tamer is a redundant independent chemical perspective of the situation, which does not require electrical or mechanical contact with the battery cells.

Nexceris has integrated its Li-ion Tamer solution across multiple market segments. In the marine and automotive industry, the gas sensors are placed on the battery module level. For utilityscale storage systems, it is typically sufficient to place sensors on each of the racks evenly, just in different zones within the containerized solution.

Stacy claims that adding its safety solution to the system would incur no more than a 1% increase in capex for any storage system. According to estimates, the fires in South Korea have created losses of around $32.8 million. Steve Cummings, director of the sensors business unit at Nexceris, points out that this includes only the actual system costs – footing the bill for the chemical clean-up, remediations, PR damage and other externalities would likely be five to tenfold that amount. And that is certainly a costly emergency to be tamed.

Read the full article here.

If you are interested in learning more about our product and how it can be integrated into your systems to prevent thermal runaway, please contact us.

| Contact us to schedule a webinar |

|---|