In an effort to increase our battery expertise, Li-ion Tamer® has been performing lithium ion battery failure testing at our facilities. These tests are intended to help us understand battery failures better so that we can provide safety products that provide value and make lithium ion batteries safe, solidifying their place in our future. We share this knowledge with our readers in hopes that our testing and conclusions help create safer battery systems everywhere.

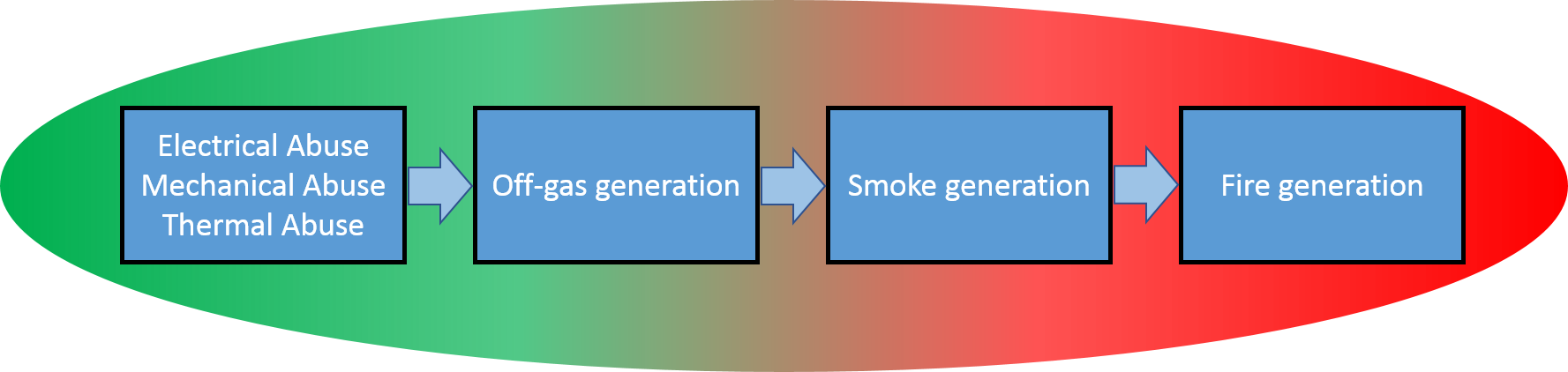

Through our failure testing, we have learned a great many things about battery failure mechanisms. By including gas detection technologies, we have noticed a clear trend in the way battery failures happen. Lithium ion battery failures have four distinct stages, shown in the graphic below.

Stage 1: Initiation abuse factor

A lithium ion battery failure is initiated by a certain type of abuse, whether it be electrical, thermal, or mechanical abuse. This stage of a failure is normally detectable by a battery management system, which is constantly monitoring the physical characteristics of the individual lithium ion batteries. The amount of time between the initiating abuse factor and the next stage, off-gas generation, largely depends on the type of abuse. For mechanical abuse, such as penetration, where the insides of the cell are immediately exposed, there will be essentially no time between Stage 1 and Stage 2. However, for abuse factors such as thermal and electrical abuse, Li-ion Tamer® has observed anywhere from 30 minutes to several hours between Stage 1 and Stage 2, depending on the intensity and type of abuse.

Stage 2: Off-gas generation

The next stage of a battery failure is off-gas generation. Different form factors lend to different reasons why this happen. For example, cylindrical cells generate off-gassing compounds because of a vent feature of the lithium ion battery cell. In pouch cells, there is a rupture in the seal which leads to an off-gassing event. This stage of failure is detectable by the Li-ion Tamer® off-gas monitor. Utilizing this detection method gives an early indication of battery failures when battery management systems are not practical, such as shipping or storage of batteries. Off-gas monitoring also provides a viable redundant sensing technique that can be used in conjunction with battery management systems in operational batteries.

Watch how taking a mitigating action at the indication of off-gassing can prevent the battery failure from occurring altogether.

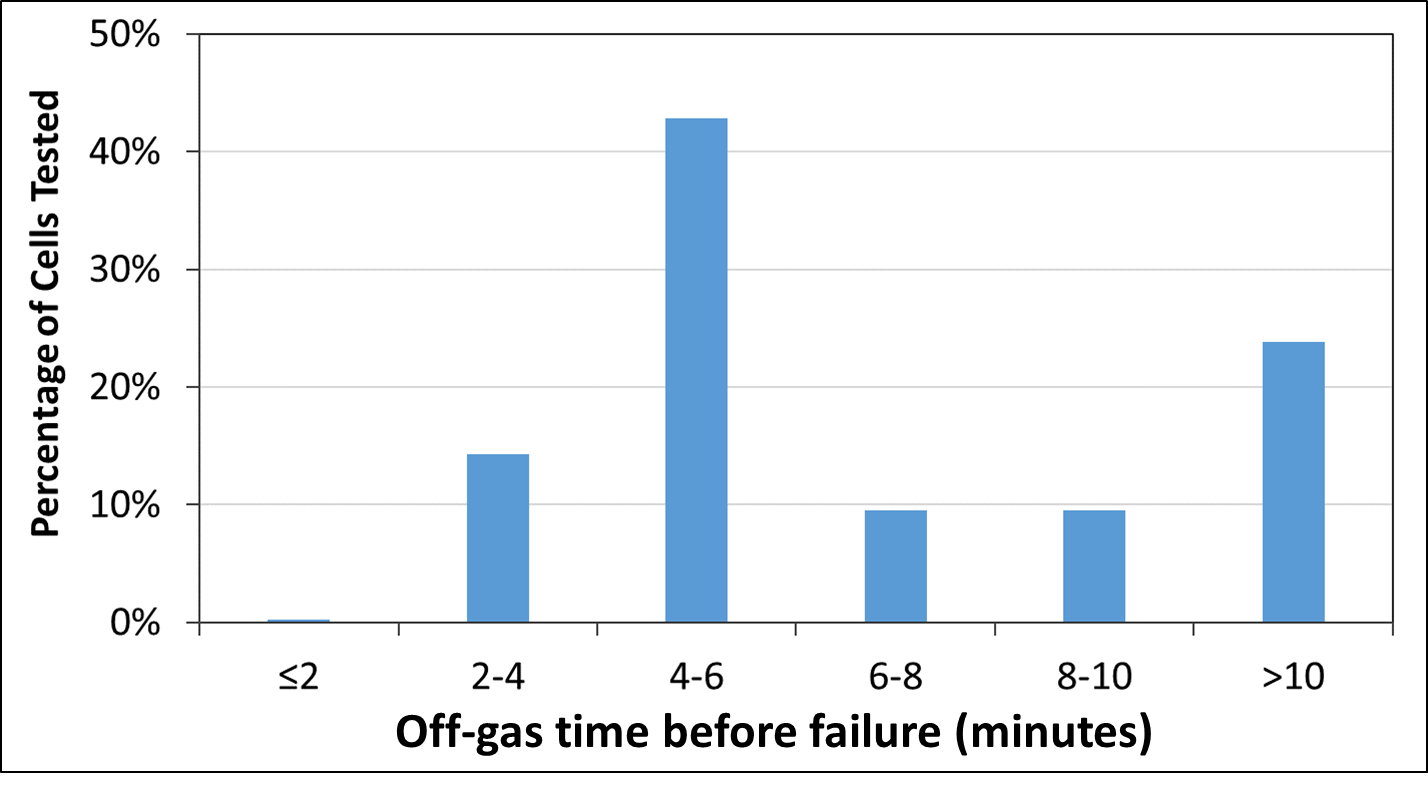

The figure above shows the amount of early warning in minutes that off-gas detection provides ahead of smoke detection. Li-ion Tamer® has shown in many instances that taking a mitigating action at the indication of off-gassing can prevent the battery failure from occurring altogether, as shown in the video below. Mitigating actions taken at smoke detection have been shown to be ineffective and, therefore, having situational awareness on when off-gassing occurs can add a large amount of value if off-gas monitoring is utilized.

Stage 3: Smoke generation

After off-gas generation, if no mitigating action is taken, the battery failure continues to progress. The generation of smoke is an indication that the cell has reached the stage of thermal runaway and the cell can experience rapid disassembly at any moment. The smoke is being generated from the inside of the battery and because the cell has already experienced a vent or rupture from the off-gassing event, the smoke will be present outside of the cell, similarly to the off-gassing compounds in Stage 2. A smoke detector would be able to detect this stage of a lithium ion battery failure and differentiate between Stage 2.

The amount of time between Stage 3 and Stage 4 is very small and sometimes Stage 3 and Stage 4 are simultaneous events. Therefore, smoke generation will provide little to no warning of lithium ion battery failures.

Smoke generation will provide little to no warning of lithium ion battery failures.

Stage 4: Fire generation

Once smoke has been generated, the battery cell is in a very unstable state and can experience fire generation or rapid disassembly at any moment. The cell is in fully developed thermal runaway and is generating its own heat and energy. The cells have metal oxide electrodes which generate their own oxygen during decomposition, adding energy and fuel to the battery fire. In a lithium ion battery pack, where there are several cells, fire generation from a single cell greatly increases the likelihood of cell-to-cell propagation, where one failing cell can propagate its failure to other cells in the pack, creating a very large and destructive event. This stage of a lithium ion battery failure is detectable by a heat detector.

Main Takeaways:

- Off-gas generation provides consistent and early warning of battery failures

- Mitigating actions taking at off-gas indication can prevent battery failures altogether

- Venting mechanisms and seal ruptures lead to off-gas generation prior to thermal runaway of a lithium ion battery cell

- Smoke generation and fire generation are often simultaneous

- Mitigating actions taken at smoke generation are ineffective

|

Test your lithium ion batteries with the experts at Li-ion Tamer® to get a battery failure analysis. |

|