The Li-ion Tamer Fault Detector is an off-gas monitoring system that increases the safety of lithium-ion battery systems. Through off-gas monitoring and localized detection, the Fault Detector is able to provide early indication of battery failures. This is done by diagnosing when an off-gas event has occurred, which occurs significantly before failure propagation and thermal runaway. Our products are capable of providing this detection capability through years of research and development. These R&D activities have resulted in

- a gas monitor that is acutely sensitive to li-ion battery off-gassing compounds,

- algorithms that enable a calibration-free and extended lifetime product appropriate for use in li-ion systems,

- and an economic product that can be scaled with lithium-ion battery racks, providing localized detection

Through the development of a robust, economical, and scalable product, we are able to deploy solutions which can provide localized detection at the battery module and battery rack level. This is much different than traditional gas monitoring, which typically provides room-level monitoring. With this type of detection resolution, not only is off-gas monitoring able to provide early detection, but it is also able to diagnose specifically where an event has occurred, which provides information that is very valuable to battery system integrators and first responders.

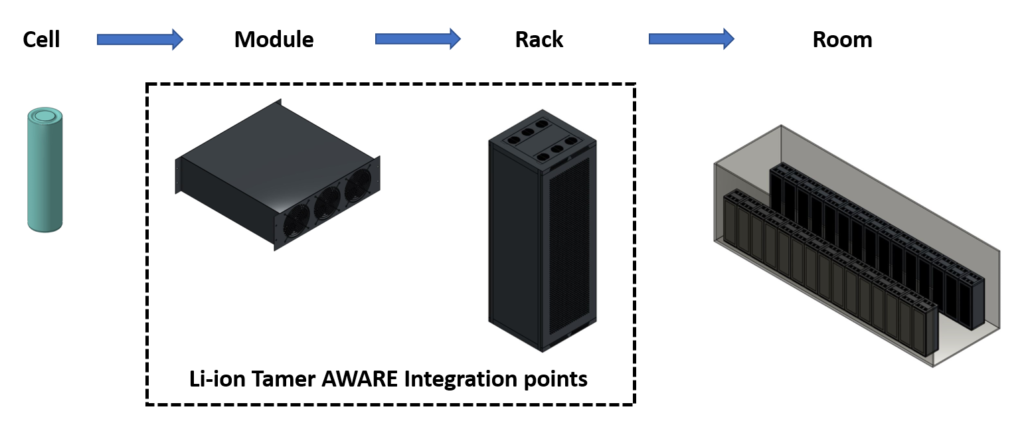

The building block of any lithium-ion battery system is a cell which are often compartmentalized within battery modules. These modules can be arranged into battery racks and several racks can be scaled to meet the demands of the application. These racks are installed within a battery room, which is essentially a dedicated space for the batteries. The Li-ion Tamer Fault Detector is a product designed to be integrated at the battery module or battery rack level, providing localized detection of these integration points.

Off-gas monitoring can provide tremendous value to a lithium-ion battery system when deployed correctly. With lithium-ion battery technology currently proliferating, many different types of li-ion systems are being designed for many different applications. It is critical that our Li-ion Tamer team remains aware of every aspect of these systems, including all the way from how cells are designed to how battery rooms are being arranged. In doing this, we are able to create the most versatile and valuable product for our customers.

Staying in tune with modern battery systems is critical when developing safety products, especially off-gas monitoring products. Our products are designed to be able to detect single cell failures, even when integrated at the rack level. Therefore, it is necessary that we understand how cells are designed, how they fail, how they will off-gas, as well as how battery modules, racks, and rooms are designed.

Our products are designed to be able to detect single cell failures, even when integrated at the battery rack level.

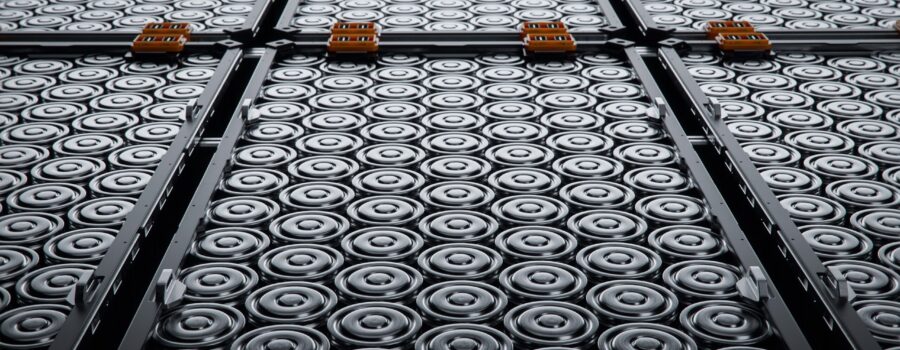

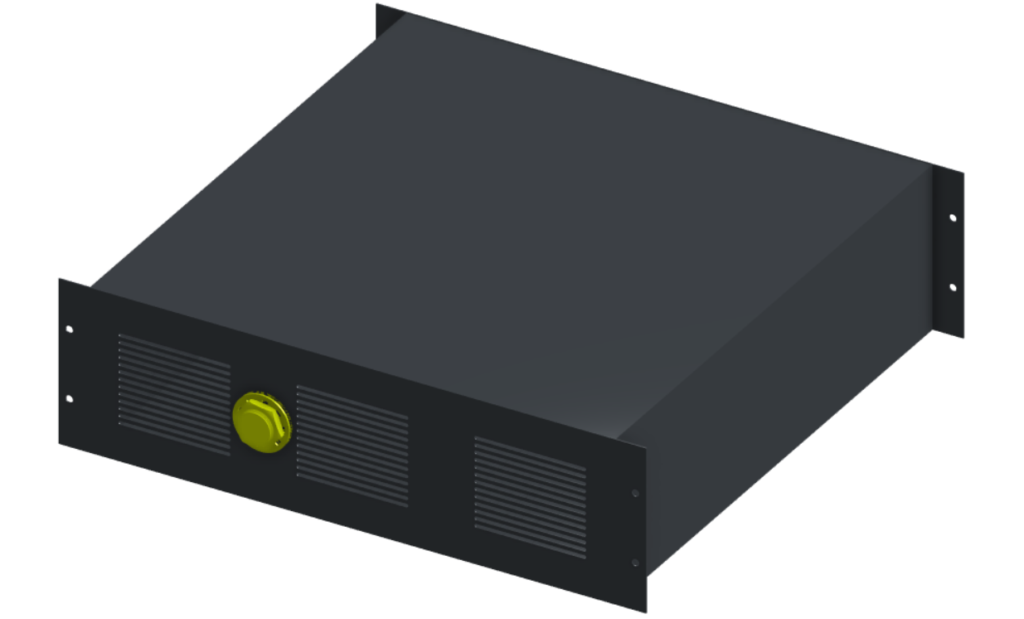

Open-air Rack Integration

The Li-ion Tamer Fault Detector can be integrated into battery racks which are comprised of open-air battery modules. This type of arrangement is often employed when battery modules are designed to be air-cooled during use. Air cooling tends to increase the longevity of battery modules by utilizing forced air convection cooling. This type of rack arrangement is standard for grid and utility scale energy storage systems.

An off-gas monitor placed at the top of the back of the rack, oriented to monitor the coolant air flow, is sufficient for detecting a single cell battery failure in a typical open-air battery rack. This arrangement is shown in the figure to the left, where the sensor is shown in yellow for increased visibility.

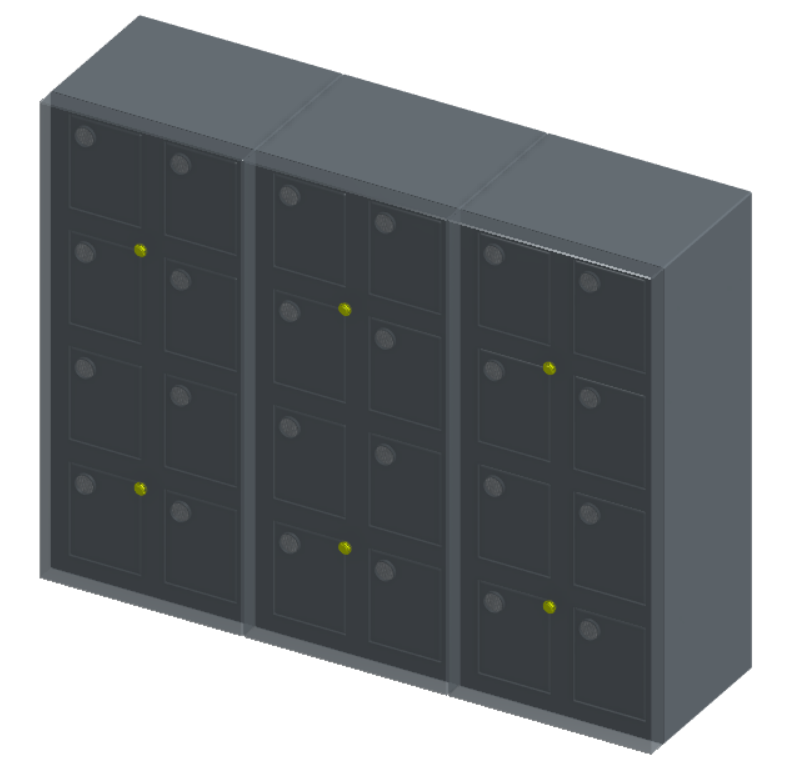

Enclosed Rack Integration

It is also possible to integrate the Fault Detector into racks that are comprised of enclosed battery modules. Depending on the application, battery modules may be sealed to protect the batteries from corrosive or hazardous environments. For example, it is typical in the the electric and hybrid marine industry that battery modules have Ingress Protection (IP) ratings of 65 or above. Liquid cooled battery modules may also be enclosed, similarly to the marine industry.

These modules are often designed with pressure relief discs that will rupture during a battery event and directionally vent the off-gassing compounds. In this situation, the Fault Detector can be implemented into the gas collection plenum. Our products include a network of sensors that increase the likelihood of detection and provide the earliest possible indication of when battery failures have taken place. An example implementation scenario is shown in the figure to the right, where two off-gas monitors (shown in yellow for increased visibility) are optimally placed in a rack of eight enclosed battery modules. Sensors are placed to provide distributed monitoring and near-immediate response times to when a pressure relief disc has ruptured and released battery off-gassing compounds into the gas collection plenum.

Module Integration

The Li-ion Tamer Fault Detector can also be integrated directly into enclosed or open lithium-ion battery modules. This implementation method will give the earliest possible warning, provide complete sensing redundancy at the module level, and diagnoses off-gas events with module-level resolution.

Let’s Get Started |

|

|---|---|

|

Take the first step in improving the safety of your battery storage systems by requesting the Rack Level Monitor today! Simply click on the button below to complete and submit the form. |

|