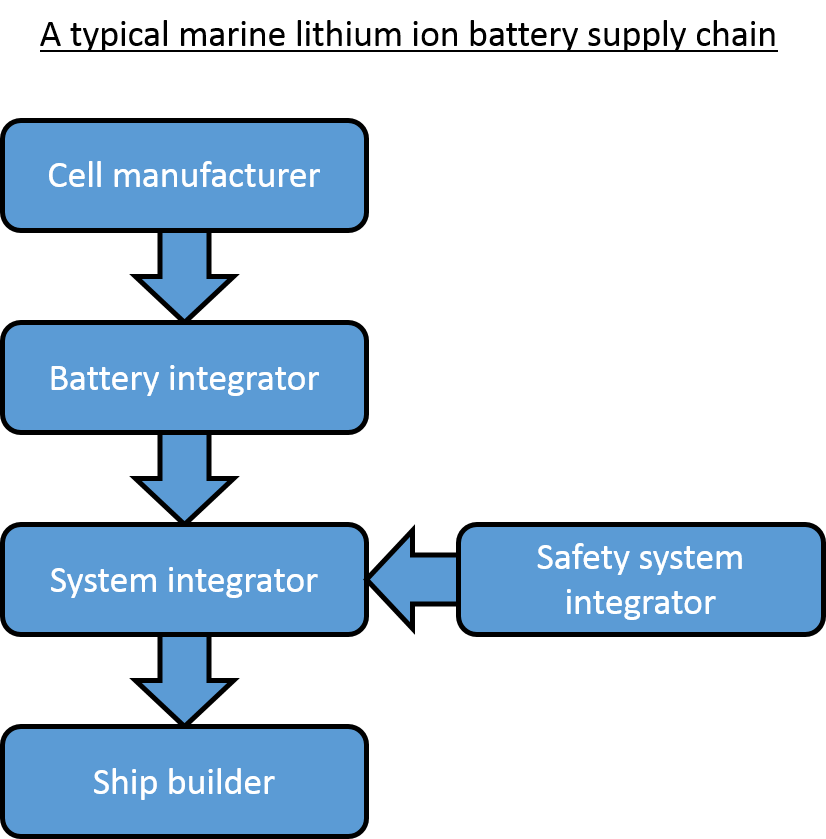

The Li-ion Tamer® group has been asked to participate in a Joint Industry Program (JIP) hosted by DNV-GL aimed at increasing the safety of marine lithium ion battery systems. In addition to increasing the safety of li-ion batteries on ships, the goal of the JIP is to incorporate the expertise of industry leaders from the entire supply chain of maritime battery installations. From conception to project execution, there are several entities involved in a battery installation, including:

Cell manufacturers

Manufacture the most fundamental part of any li-ion system, the cells

Battery integrators

Integrate battery cells into modular product, often known as a battery module or battery pack with local battery management systems and various safety features

System integrators

Integrate battery systems into ship’s electrical architecture so the battery can be appropriately used by the ship

Safety system integrators

Integrate safety solutions into battery systems, such as battery monitoring systems (see blog post about battery monitoring systems)

Ship builders

Build the ships which must include space and the proper equipment for integrating large format lithium ion batteries

A critical component of the DNV-GL JIP is that they have chosen to incorporate safety system integrators into the program. By alleviating the duty of the system integrator to provide additional safety features, companies with novel monitoring technologies and fire suppression approaches are eager to step up and provide state-of-the-art safety solutions for marine applications.

The two-year program involves several state-of-the-art activities. These will include:

Development of a battery off-gas model

This task comprises of improving current industry knowledge about battery off-gassing mechanisms. This will include battery off-gassing as an input to dispersion and explosion modeling practices.

Lithium ion battery risk assessment

The risk assessment will utilize JIP partner knowledge and design practices as input to the DNV-GL risk assessment process. The process will identify and assess failure mechanisms, battery off-gas and dispersion, thermal events and ignition sources, as well as risk mitigation and safety mechanisms

Battery safety testing program

Cell and module failure testing with extensive instrumentation will be performed. An emphasis will be placed on off-gas contents and release rates, thermal runaway and heat loads, ventilation and dispersion measurements, ignition, explosion and fire risks, submersion, effect of risk mitigation, and testing of high rate cooling via extinguishing

Battery safety simulation and analysis tool development

A compilation of analytical and experimental results will be done with the intention to build tools and rules of thumb to be used as the basis of design requirements and risk analysis for battery systems.

Project management, dissemination, input to requirements and rules

The evaluation of project conclusions and outputs to provide information in the context of existing authority requirements and DNV-GL class rules

Off-gas monitors are shown above, which is an example of some hardware that Nexceris will provide for the JIP.

Li-ion Tamer is looking forward to providing its expertise and products to help the advancement of the program and to improve safety of maritime lithium ion battery systems everywhere.

While li-ion battery events are rare, they do happen. By recognizing this, we can take the necessary steps to improve our battery safety, handling, and usage, making the world a safer place. If you need help getting started, contact our lithium ion battery safety experts at info@liiontamer.com for a free battery safety consultation.

|

Let us help make your technology safer. |

|

|---|---|

|

Contact us for a free consultation with our battery experts and discover ways to improve the safety of lithium ion batteries in your specific application. |

|